DTF printing, or Direct-to-Film printing, is transforming the landscape of custom apparel by offering innovative solutions that capture attention and enhance creative expression. This cutting-edge technology is rapidly gaining popularity due to its numerous benefits, such as vibrant colors and compatibility with various fabric types, making it a top choice for businesses wanting to produce eye-catching designs. In this introductory article, we will delve into the myriad of DTF printing advantages that not only benefit printers but also cater to customer demands for quality and variety. The ability to create exceptional prints on t-shirts and other garments ensures that the artistry of custom apparel shines through. As we discuss these compelling benefits of DTF printing, it’s clear this method is poised to lead the future of garment decoration.

Often referred to as film transfer printing, DTF technology stands out for its remarkable ability to reproduce detailed and colorful designs on a variety of apparel materials. This revolutionary method, utilized in the world of custom clothing, caters to the creative needs of brands looking to make their mark with striking visuals. As designers and businesses alike explore the possibilities offered by this printing process, they recognize the significant advantages it presents, including its efficiency and environmental considerations. The introduction of DTF as a preferred choice for t-shirt printing reflects the broader shift toward innovative apparel solutions that align with consumer expectations. By harnessing the capabilities of DTF printing, businesses can elevate their offerings and meet the ever-evolving demands of the market.

The Vibrance of DTF Printing: How Colors Come Alive

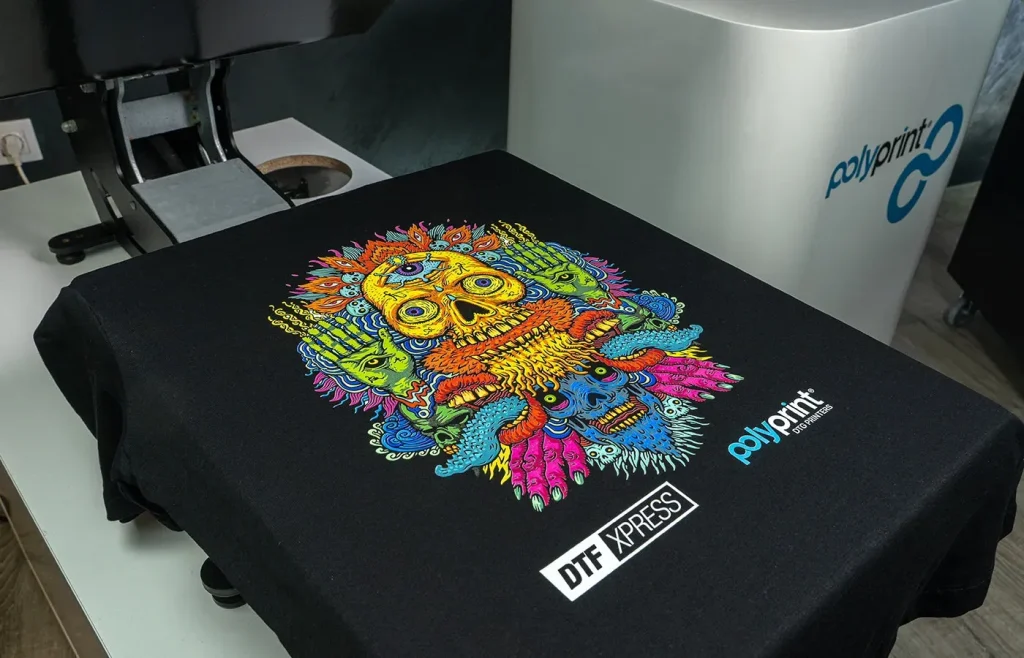

DTF printing is renowned for its ability to generate rich, vibrant colors that truly capture the essence of any design. Unlike traditional printing methods that can sometimes lead to dull or muted outcomes, DTF’s technology ensures that the colors remain true to the original artwork. This quality is particularly crucial in custom apparel, where apparel designs need to stand out to attract consumers. Whether it’s for bold t-shirts that demand attention or subtle details within a fabric, DTF’s vibrant palette allows for creative freedom and visually striking results.

Moreover, the clarity and precision offered by DTF printing mean that intricate designs can be rendered beautifully. From fine gradients to detailed artwork, this printing technology keeps the quality intact even after multiple washes. As a result, businesses can confidently promote their custom apparel, knowing that the vibrant colors will last and maintain their impact over time. This aspect not only enhances customer satisfaction but also aids in building brand recognition, as designs remain crisp and lively on the garments.

DTF Printing Advantages: Expanding Material Compatibility

One of the most significant advantages of DTF printing lies in its compatibility with a wide range of materials. Unlike traditional methods that may be limited to certain fabrics, DTF can be successfully applied to polyester, nylon, cotton, and various fabric blends. This versatility is crucial for businesses that aim to offer a diverse range of custom apparel options to meet their clients’ varying needs. By utilizing DTF printing, companies can explore new avenues for design and product innovation without being restricted by fabric choices.

Furthermore, this wide material compatibility not only broadens the product lineup but also reduces the need for multiple printing setups or processes. As the fashion industry increasingly embraces diversity in materials, DTF technology positions businesses to adapt and thrive in a competitive landscape. Whether creating performance wear or fashionable streetwear, DTF opens doors to new opportunities, making it easier for companies to cater to niche markets while maintaining high-quality standards.

Cost-Effectiveness: DTF Printing for Small Runs

For startups and small businesses in the custom apparel space, cost-effectiveness is paramount. DTF printing shines in this area, allowing companies to produce high-quality prints without incurring unnecessary costs. Traditional screen printing often requires extensive setup time and material outlay, which can be prohibitive for small orders. DTF, however, streamlines this process, enabling efficient production of small batches without compromising on quality or detail.

This affordability not only helps new businesses establish themselves but also allows them to experiment with different designs and fabrics without the fear of wasting resources. With DTF printing, entrepreneurs can build their brand presence by creating unique and customizable apparel, attracting a loyal customer base while keeping overheads manageable. By leveraging the cost-effective nature of DTF technology, small businesses can focus more on creativity and marketing rather than logistical expenses.

Sustainability Matters: The Eco-Friendly Edge of DTF Printing

In an age where consumers are increasingly concerned about sustainability, DTF printing stands out as a responsible choice for custom apparel production. Utilizing water-based inks, DTF minimizes harmful emissions typically associated with traditional printing methods. This eco-friendly approach aligns with the values of many contemporary brands that prioritize environmental consciousness, allowing them to appeal to a broader audience.

Additionally, DTF printing techniques encourage better material utilization through gang sheets, where multiple designs are printed in one run, leading to reduced waste. This not only conserves resources but also enhances operational efficiency for businesses. By adopting DTF printing, companies can make a significant impact on their sustainability goals while also strengthening their brand image as environmentally responsible players in the custom apparel market.

The Quick Turnaround Advantage: DTF Printing for Modern Demands

In today’s fast-paced retail environment, where trends change rapidly and customers expect quick service, DTF printing offers a significant advantage with its fast turnaround times. This speedy production capability allows businesses to keep up with market demands, fulfilling orders promptly and reducing the waiting time for customers. Whether for last-minute promotional events or seasonal launches, DTF printing ensures that companies can respond to customer needs effectively.

This efficiency not only benefits customer satisfaction but also enhances brand loyalty. Companies that can consistently deliver quality products on time secure their reputation in the competitive custom apparel landscape. DTF printing’s quick turnaround capability supports businesses in minimizing delays, resulting in a streamlined production process that helps brands maintain their edge in the market.

Flexibility in Design: Unlocking Creativity with DTF Technology

DTF printing technology provides remarkable flexibility in design, allowing for intricate graphics and detailed patterns that are often challenging to achieve with traditional methods. This adaptability means that designers can explore their creativity fully, implementing complex designs, gradients, and various artistic elements without compromise. Custom apparel creators are thus empowered to transform their visionary concepts into wearable art precisely and flawlessly.

Moreover, the ease with which DTF printing accommodates various design elements enhances the overall customer experience. As businesses offer customizable options, consumers are more likely to engage and make purchases, knowing they can obtain unique apparel that reflects their personal style. This unique selling proposition fosters stronger connections between brands and their audiences, amplifying the appeal of custom designs in a saturated market.

Frequently Asked Questions

What are the main advantages of DTF printing for custom apparel?

DTF printing offers several advantages for custom apparel, including vibrant color reproduction, compatibility with various fabric types, and cost-effectiveness for small runs. Additionally, it minimizes waste through efficient use of materials, produces durable prints, allows for quick turnaround times, and provides flexibility in design capabilities.

Is DTF printing suitable for t-shirts of different materials?

Yes, one of the key benefits of DTF printing is its wide material compatibility. It works effectively on various fabrics such as cotton, polyester, nylon, and blends, making it an excellent choice for custom t-shirts regardless of the material.

How does DTF printing compare to traditional printing methods?

DTF printing surpasses traditional methods like screen printing by providing higher quality prints with vibrant colors and detailing. Additionally, it is more cost-effective for small batch orders, reduces waste, and offers quicker production times, making it a modern solution for custom apparel.

What are the eco-friendly aspects of DTF printing?

DTF printing utilizes water-based inks, which are safer for the environment compared to traditional inks. This method also promotes reduced waste through the use of gang sheets, aligning well with sustainability practices sought by many custom apparel businesses.

Can DTF printing accommodate intricate designs?

Yes, DTF printing technology supports intricate graphics and complex designs, allowing for detailed artwork, gradients, and fine lines. This flexibility in design makes it an ideal choice for creating unique custom apparel.

What makes DTF printing a cost-effective option for small businesses?

DTF printing is cost-effective for small businesses because it eliminates the need for extensive setup, which is often required in traditional screen printing. This efficiency allows for affordable production of small batch orders without sacrificing quality.

| Benefit | Description |

|---|---|

| Vibrant Colors | Produces bright, vibrant colors true to the original artwork, ideal for visual appeal in custom apparel. |

| Wide Material Compatibility | Compatible with a variety of fabrics such as polyester and nylon, allowing for product diversity. |

| Cost-Effective for Small Runs | Ideal for small batch orders due to minimal setup costs, making it a great option for startups. |

| Less Waste | Utilizes gang sheets and reduces ink and fabric waste, aligning with sustainability goals. |

| Durable and Long-Lasting Prints | Prints withstand multiple washes without losing quality, making them suitable for everyday wear. |

| Quick Turnaround | Enables swift production and delivery, enhancing customer satisfaction in a fast-paced market. |

| Ease of Use | User-friendly technology accessible for both large businesses and startups. |

| Ability to Create Transfers | Allows for the production of customizable transfers that can be applied to various garments. |

| Flexibility in Design | Supports intricate graphics and details, giving designers creative freedom. |

| Eco-Friendly Printing Options | Utilizes water-based inks, contributing to a safer and more sustainable printing process. |

Summary

DTF printing has emerged as a transformative technology in the custom apparel sector, offering unique benefits that are reshaping garment decoration. Its ability to deliver vibrant colors on a variety of fabrics makes it a preferred choice among businesses seeking to enhance their product offerings. Moreover, DTF printing’s eco-friendly approach, coupled with its cost-effectiveness for small production runs, reduces waste while ensuring durability and high-quality outputs. Altogether, these advantages position DTF printing as a vital component for companies aiming to innovate and stay competitive in the custom apparel landscape.